My trip to Douala

Designing a prototype in Cameroon

Meeting the school

One of the first things I did when arriving in Cameroon is to meet the school. I got in contact with Collège NAL, a bilingual school of around 2500 students in Douala. I explained the students what I did so far at the welder and showed them, using my sketches, what they could expect at the end of my visit. I met the students of the ‘blue team’, students responsible for Cleanup program of the school. I asked about their opinions and did some interviews to get to know them better. Throughout the process, Collège NAL was very supportive and cooperative.

Constructing the frame was an iterative process in which I explained my solidworks drawings to local welders. There where multiple options for the top bending part so 3 variants where built and tested. Also, in terms of stability of the frame, 2 different configurations where built and tested. At last, the frame was finished by adding rubber protective parts at the end of the profiles and adding a protective coating.

Constructing the frame

Bending part design

To remove the bags easier the first idea was to make the top bending part hinged. 2 hinges on the frame makes the bending parts hinge inward. The problem with this solution is that when a bending part hinges inward it is to high to reach.

To make the hinged bending part less high to reach a new double folding bending part was tested. This part eventually appeared too complicated.

The final result is a bending part that slides into the frame. Therefore removing the part is easy and the user doesn’t have to reach too high.

Base design

To goal of this base was to place tiles in the square cadre so the frame would be stable. The cadre appeared too big and heavy for easy transport.

By making the first base we discovered that the amount of metal used was too much. The same frame could be made stable with less metal, therefore this new configuration was made. The central profile of the frame was stabilized with small profiles.

Final refinements

The EcoBin will be placed on school playgrounds, this means games will be played around the bin. If the upper profiles aren’t protected, accidents can happen by bumping into a scharp profile edge. Therefore the upper profiles are protected with a piece of rubber.

Rust makes the frame rough and doesn’t look good, the frame was covered with a protective black coating.

When building the prototype, we realized that the bags we bought where slightly too big for the frame. Therefore we made the central profile extendable. This also helps with stretching out the bigbags.

Prototyping the bigbags

The bigbags in the final renders are personalized ones that are meant to be ordered in Asia. Because the use of personalized bigbags would be costly for the prototype we tried to make our own personalised bags by reknitting standard bigbags that we bought at a local market.

Eventually graphics were added to the bigbags by co-creating and painting with students of collège NAL.

The bigbags where bought at a local market. We bought bigbags with a lenght of 1,50 meter and a closed top and bottom on the top there was a discharge spout.

We took the bigbags to another market to search for a knitter. We found a bagvendor who could make the top and downflaps from cutted shopping bags.

The 2 flaps were knitted on the top and downside of the bag.

One adjusted bigbag was tested on the frame and after that we let the bagvendor make another bigbag.

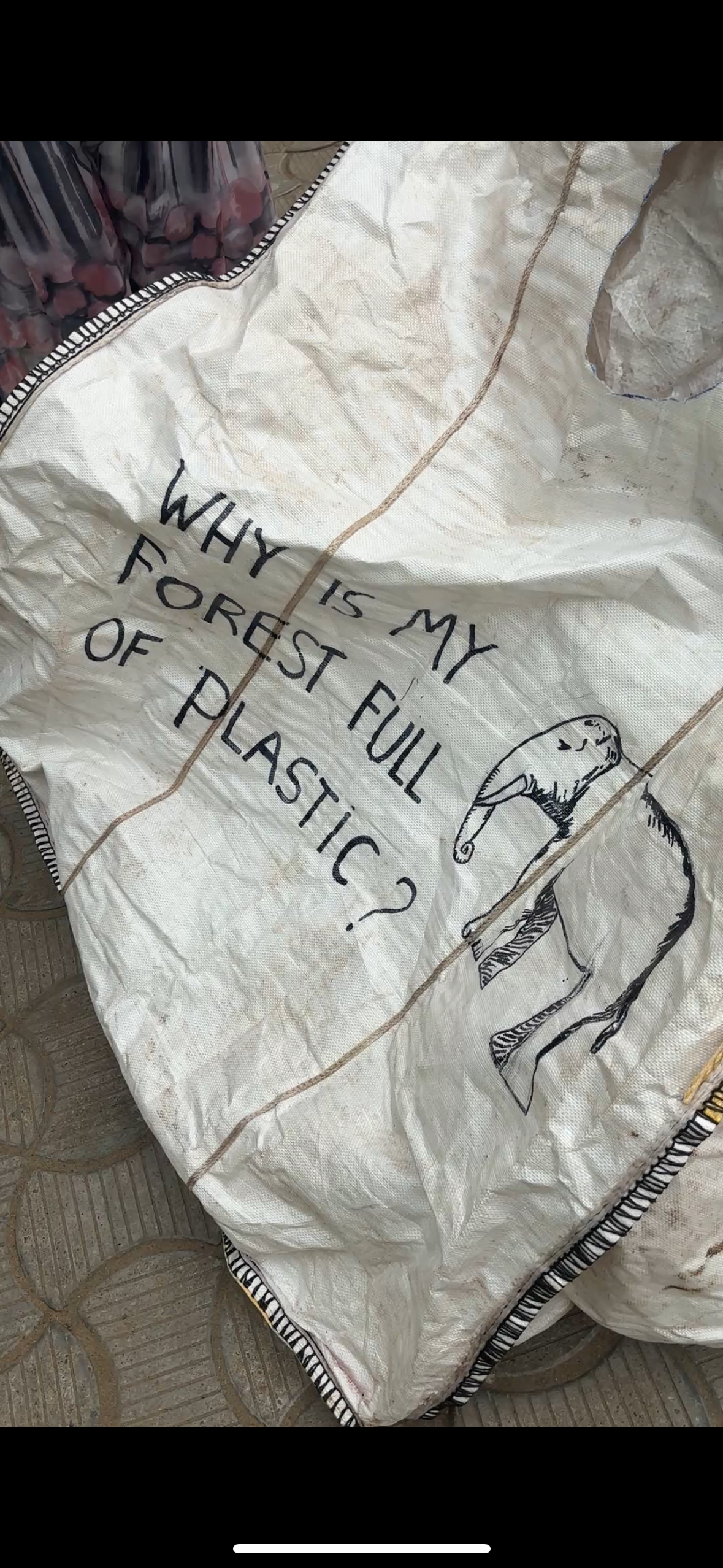

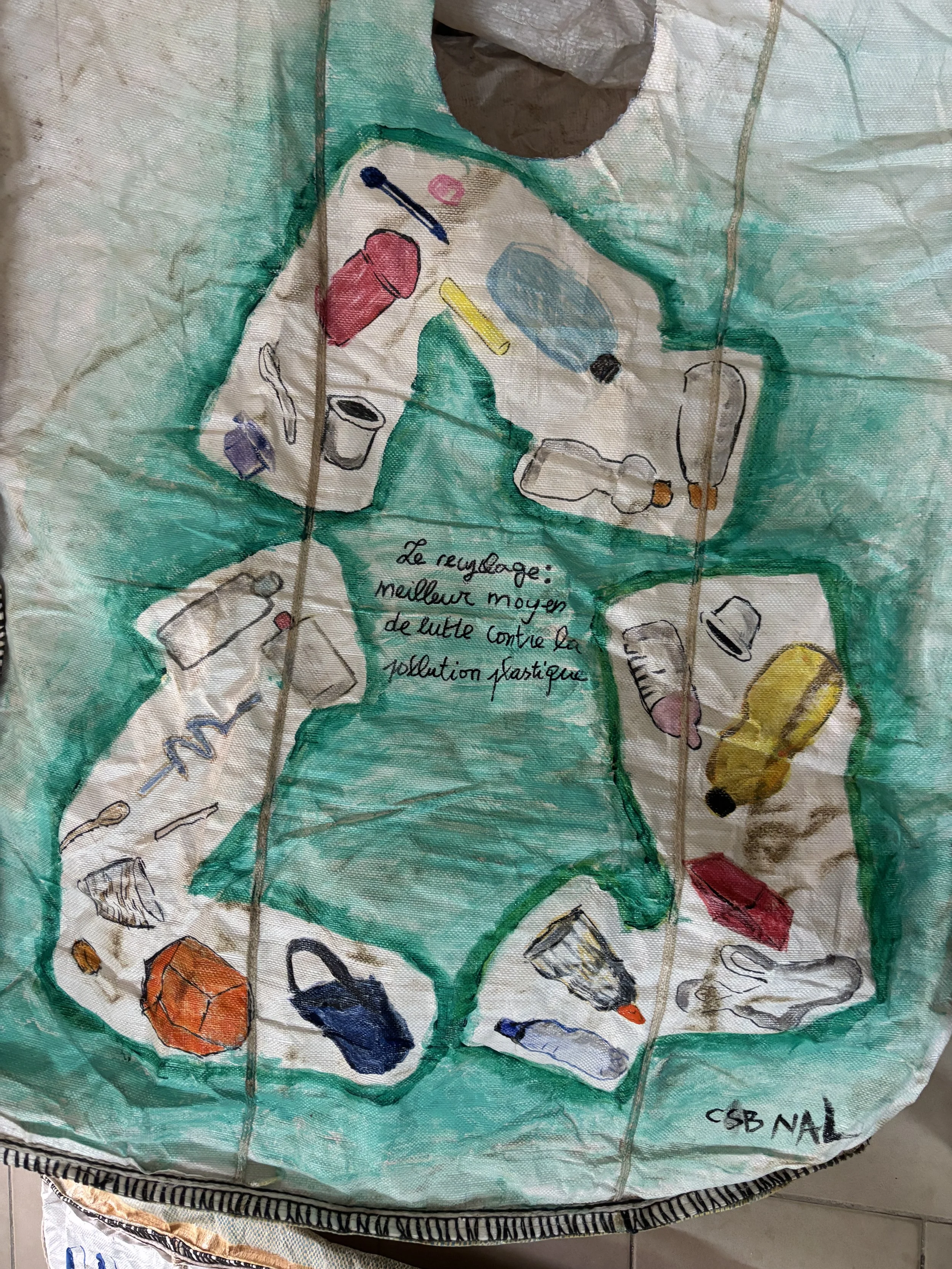

Once the holes where made and the bigbags were adjusted to the frame, I drew an elephant with a slogan about plastic waste as an example for the students. After that, I let them decide for themselves what they wanted to put on their bigbags. The only condition was that it had to be about recycling plastic waste or the consequences of plastic waste.

I was very surprised by the results I saw 2 days later, together with their art teacher they used acrylic paint to draw very nice and beautiful messages on the bigbags of my prototype.

By drawing they were actively stimulated to think about recycling and the message they want to convey to the rest of the school. Therefore the result was not only beautiful but it was also a learn full activity.

Final result

Eventually the frame was taken to the school, bigbags were installed and the students used the new prototype to dispose of their bottles. The disposal was observed and the bigbag was weighed, therefore we concluded that one bag could contain around 50kg of bottles. This means that the entire prototype, when 4 bags are installed, can contain 200kg of bottles and cups. This is around 4 times the volume of the previous bin.